No, drone technology is not going away. In fact, its use in the professional services marketplace is only expanding. One application we’ve developed expertise in is utilizing UAS to analyze landfills.

No, drone technology is not going away. In fact, its use in the professional services marketplace is only expanding. One application we’ve developed expertise in is utilizing UAS to analyze landfills.

Landfills are often run as a business, and, like any business, operators make decisions based on metrics and try to increase efficiencies to improve the bottom line. With landfills, this comes down to how much discarded matter you can fit before the area is full. The better you compact the trash, the more you can fit – increasing capacity and life within the landfill.

So how can an unmanned aerial system, or UAS, help?

It can help more than most people realize, particularly when it comes to landfill applications.

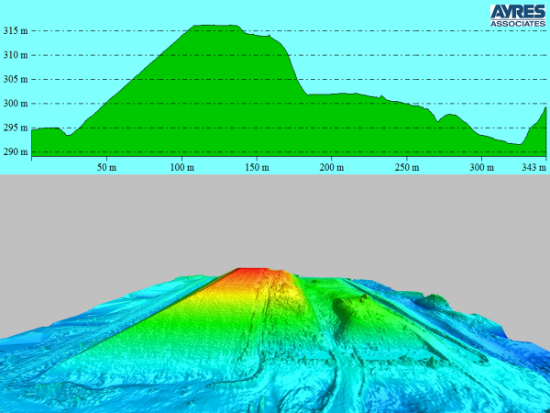

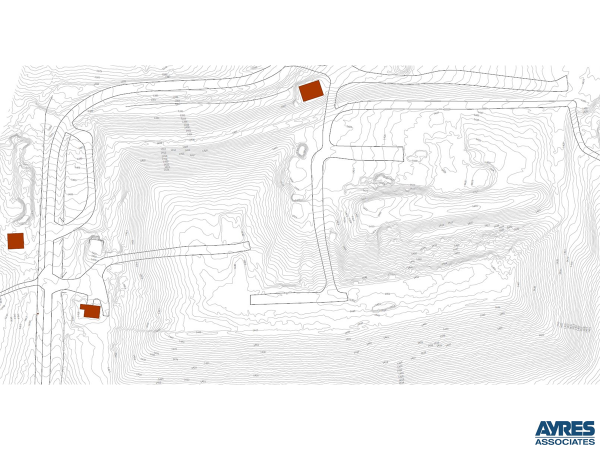

Our team has completed multiple UAS missions at the Adams County (Wisconsin) Landfill, for example, using  information gathered to provide detailed topographic mapping data about the site and surrounding terrain. We’ve been using our UAS-gathered information to create three-dimensional surface models to support volumetric calculations and change detection analysis.

information gathered to provide detailed topographic mapping data about the site and surrounding terrain. We’ve been using our UAS-gathered information to create three-dimensional surface models to support volumetric calculations and change detection analysis.

Landfills are licensed to hold a certain amount of material, dictated by the available airspace. As material piles up, the landfill’s limit will eventually be reached. Historically, we assessed this by sending surveyors into the field to collect measurements, but drone technology allows us to more efficiently provide this information – and then some. Whereas traditional survey provided a point of information once every 50-feet, drone technology can deliver survey shots every two centimeters – giving our landfill operators a more complete picture of the available airspace and how much volume they have left to fill.

Additionally, with traditional survey methods, we typically focus on an explicit spot within a landfill where a landfill  manager knows change has occurred in recent months. A UAS can quickly (and economically) fly an entire project site, providing a more complete picture and looking for other areas of change due to subsidence or erosion.

manager knows change has occurred in recent months. A UAS can quickly (and economically) fly an entire project site, providing a more complete picture and looking for other areas of change due to subsidence or erosion.

If you plan to use the imagery as more than just a picture, such as the geospatial analysis described above, you will need to know more than simply how to fly a UAS. You should also factor in:

- Surveyed ground control. This is the key to lock all data to known locations.

- Quality flight planning. Proper planning allows for the right data to be collected for a specific analysis.

- Good environmental conditions. Optimal conditions involve clear skies and low wind – and avoid rain, snow, and fog.

- Understanding of photogrammetry. Simple push-button drone software is good at quick-and-dirty photo processing but leaves random errors which can skew analysis.

- Understanding of surface generation. For an accurate product from imagery or a point cloud, significant editing will be needed to remove noise and non-surface features.

- Understand the limits of your technology. If you’re using a camera system to measure the ground in an area with leafy trees, high grass, or dense crops, recognize that you might need to use a different technology. Ground features will be better captured during “leaf-off” seasons where obstructions like these are minimized.

UAS may never replace the human element of a professional survey or inspection, but this technology is already  proving to be a useful tool to provide high-density data and analysis over entire project areas while limiting the time humans need to spend in hazardous environments.

proving to be a useful tool to provide high-density data and analysis over entire project areas while limiting the time humans need to spend in hazardous environments.

So, unless you crash your UAS into a tree or back over it with your car, your UAS should be safe from the trash can. But, if the unfortunate does happen, Ayres Associates may be using our UAS to help assess just how much space yours is taking up in your local landfill.

Background

Ayres Associates currently has four pilots in command, and we complete our UAS projects in accordance with the FAA’s Part 107 guidelines. Our pilots each complete strict internal training, both in the lab and in the field. All Ayres projects follow strict safety protocols, and our personnel invest the time needed to understand and appreciate the risks of the work environment before deploying UAS equipment.

FAA’s Part 107 guidelines. Our pilots each complete strict internal training, both in the lab and in the field. All Ayres projects follow strict safety protocols, and our personnel invest the time needed to understand and appreciate the risks of the work environment before deploying UAS equipment.

When Ayres incorporates UAS on a job, we can say with confidence that we’ve carefully weighed the pros and cons of implementing this emerging technology on the project. Delivering high-quality products to our clients is our No. 1 goal, and, in certain circumstances, we’re finding UAS to be a helpful tool to meet that objective.

Recent Comments